- Sydney: +61 2 9096 2621 kenny@finework.com.au

- Auckland: +64 9 354 4836 minka@finework.co.nz

Our Services

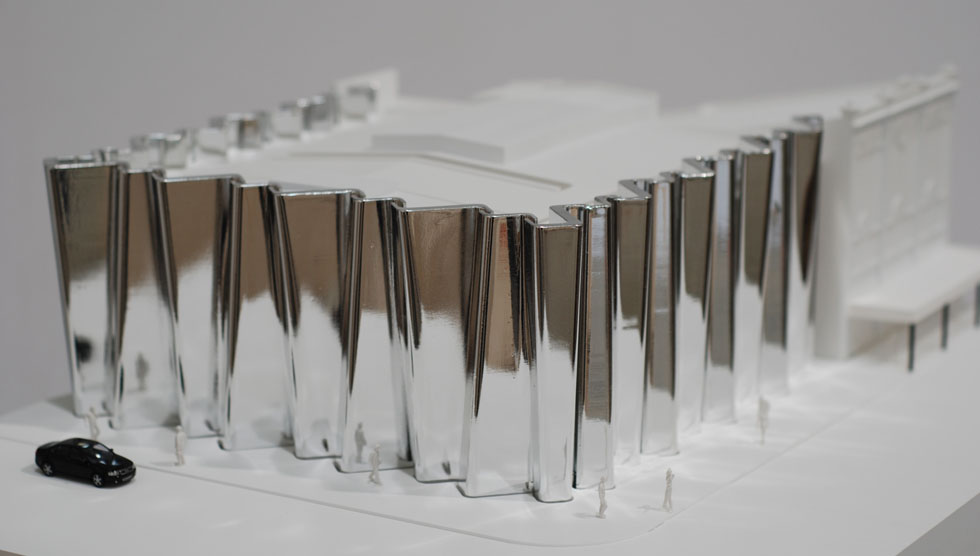

At Finework, we embrace both the modern technology and traditional craftsmanship. We make high quality architectural models and provide exceptional service to our clients.

At Finework we specialise in:

Model Making & Object Fabrication

As every object and every project is never the same, we ask that you provide us drawings to scale such as:

From here we can discuss with you further.

3D Printing

We do all our 3D printing in-house, with the help of the Projet 3500HDMAX. It uses a MultiJet printing technology, offering UV-curable plastic in a range of translucencies and tensile strength. This produces an accurate, precise and high resolution.

Strong ABS plastic can be printed white or semi-clear. Ideal for creating functional prototypes and wax models that can be use for investment casting.

Using priority courier, rest assured you’ll receive your printed part promptly, whether you live in Australia or New Zealand

Laser Cutting

General Info

Acceptable formats

The maximum file size we accept is 5mb.

Delivery Options

You can pick up from store or have it posted to you. Discuss with us the available options.

Drawing Tips

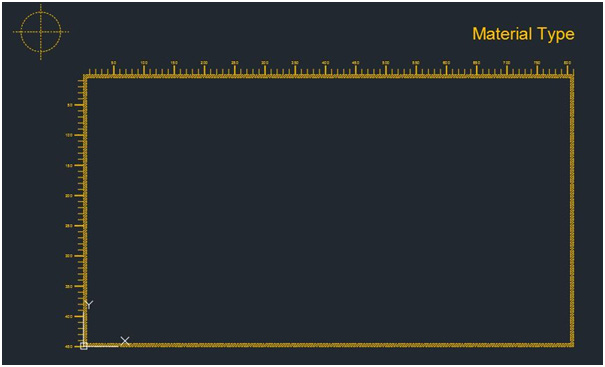

- Keep the drawings as clean and simple as possible. Use the template provided.

- Remember that curves take longer (and therefore cost more) than straight lines.

- Allow a margin around the border of the material of at least 5mm. Table size is 810mm x 450mm, and cuttable area is 800mm x 440mm.

- Make sure there are no duplicate lines, as these will add to cutting time and cost, and may cause burning.

- Make sure to save all your text as curves or objects so that your drawing isn't affected if we don't have the font you were using.

- If supplying your own material, include at least one spare piece of material, in case of drawing or cutting errors. Remember to label the material to be used.

- Allow for slight variations in material thickness, especially if your pieces need to fit tightly together. Call to discuss this if unsure, but don’t aim for a press-fit.

- Some material will be lost on the laser-cut line itself, especially in thicker materials. This can vary from 0.1 to 0.5mm depending on the thickness of material used.

- There is almost always a slight taper to the cut, due to more laser power at the entry point (top surface) of any material. This is more apparent in thicker material.

- For best results work from our template drawing or at least include one labelled box 810mm x 450mm in orange on your drawing.

Linework and colour

Thickness - All lines should given the minimum setting for your program.

Cut lines - Any line that you wish to cut all the way through the material should be drawn in the cut layer or blue colour.

Score lines - Lines that you want to simply score or engraved onto the surface of your material should be drawn in the vector layer. Note there is a light engraving or deeper engraving.

Rastering - Areas to be engraved as a block fill onto the surface of your material should be on the raster layer or have a red colour and fill.

instructions - should be in orange colour and will be ignored by the laser.